Key Growth Drivers of Manufacturing in India in 2025

India's manufacturing sector is witnessing a transformative phase, driven by a confluence of global strategies, government initiatives, and evolving market dynamics. From leveraging geopolitical shifts to introducing robust domestic policies, India is positioning itself as a key player in the global manufacturing landscape. In this article, we explore the pivotal factors driving this growth.

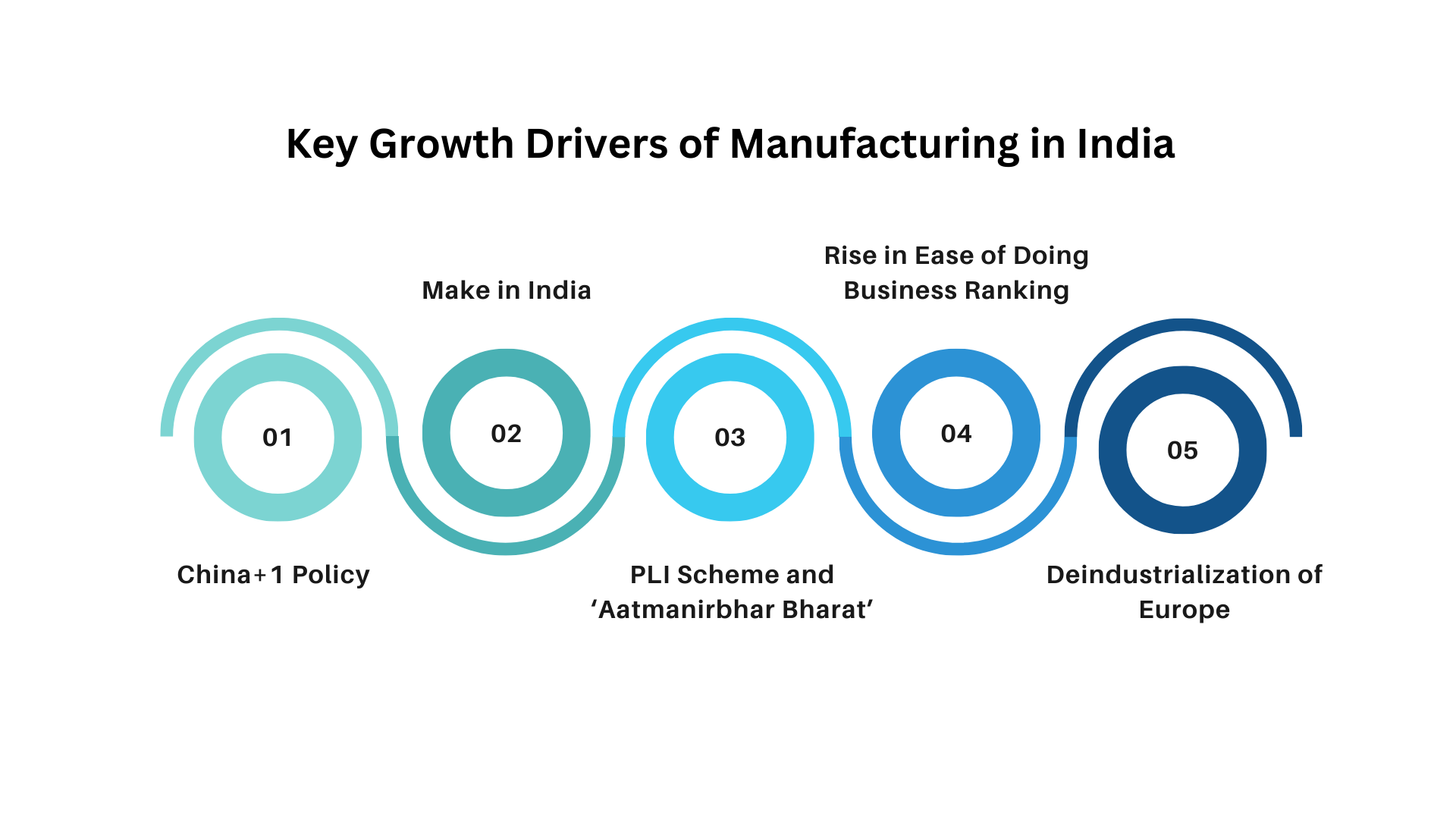

Key growth drivers influencing India's manufacturing sector in 2025.

China+1 Policy: A Strategic Shift

For decades, China has dominated the global manufacturing arena, hosting industries from technology and heavy engineering to textiles. Its low-cost labor and developed infrastructure attracted global giants, including Airbus and Boeing. However, rising geopolitical tensions and trade differences have exposed the risks of overdependence on China. The United States and other nations are now diversifying their supply chains under the China+1 strategy, aiming to mitigate risks while ensuring supply chain resilience.

The impact of this strategy is evident in sectors like textiles, where U.S. sourcing from China dropped from 36% in 2015 to 20% in 2021. Electronics, cosmetics, and IT are among other industries following this trend, with countries like Vietnam, Bangladesh, and India reaping the benefits. In India, major players like Foxconn and Apple have already established manufacturing units, bolstering the country's position in global value chains.

Make in India: A Transformative Campaign

The "Make in India" initiative is revolutionizing the country's manufacturing ecosystem through targeted policy interventions, infrastructure development, and skill enhancement. Key measures include:

- Policy Interventions: Simplifying regulatory frameworks, streamlining procedures, and eliminating bureaucratic hurdles to create a business-friendly environment.

- Infrastructure Development: Significant investments in transportation, logistics, and supply chain modernization to enhance connectivity and efficiency.

- Skill Enhancement: Educational reforms and vocational training programs to equip the workforce with modern manufacturing skills.

- FDI Attraction: Encouraging foreign direct investment in critical sectors such as automotive, electronics, aerospace, and defense.

- Promoting Indigenous Manufacturing: Strengthening supply chains and fostering self-reliance to empower Indian enterprises for global competitiveness.

Success stories under this initiative include partnerships like GE and Alstom's locomotive production in Bihar, Airbus and Tata's helicopter assembly facilities, and the operationalization of the C295 plant in Gujarat by November 2024. Additionally, India's Light Combat Aircraft program, led by Hindustan Aeronautics Limited (HAL), has emerged as a beacon of indigenous manufacturing success.

PLI Scheme and 'Aatmanirbhar Bharat'

The Production-Linked Incentive (PLI) scheme is a cornerstone of India's efforts to boost manufacturing competitiveness and reduce import dependency. Offering incentives tied to incremental production and sales, the PLI scheme targets key sectors like electronics, automobiles, pharmaceuticals, and textiles. By fostering local manufacturing, it aligns with the broader vision of 'Aatmanirbhar Bharat' (self-reliant India).

For instance, the PLI initiative has spurred growth in electric vehicle (EV) components manufacturing. As of 2023, 2,952 products out of the 4,666 identified for indigenization under 'Aatmanirbhar Bharat' have been successfully localized, further cementing India's industrial capabilities.

Ease of Doing Business: A Rising Index

India's climb in the World Bank's Ease of Doing Business rankings, from 142nd in 2014 to 63rd in 2019, highlights significant strides in regulatory reforms. The implementation of the Goods and Services Tax (GST), simplification of business registration processes, and improvements in construction permits and credit access have collectively enhanced the business environment. This upward trajectory reflects the government's commitment to fostering an investor-friendly ecosystem.

Deindustrialization of Europe: An Emerging Opportunity

The gradual deindustrialization of Europe, driven by technological advancements, changing market dynamics, and global competition, presents a unique opportunity for alternate manufacturing hubs. European manufacturers face challenges in maintaining competitiveness amidst automation and digitalization. This shift creates space for countries like India to emerge as high-quality manufacturing bases, leveraging cost advantages and a skilled workforce to attract global investments.

Future Outlook

India's manufacturing growth story is underpinned by strategic global shifts and robust domestic policies. Initiatives like China+1, Make in India, the PLI scheme, and improvements in ease of doing business underscore the country's ambition to become a global manufacturing powerhouse. Coupled with opportunities arising from Europe's deindustrialization, India is well-positioned to lead the next wave of industrial transformation. As the country continues to build on these foundations, the future of manufacturing in India looks promising.